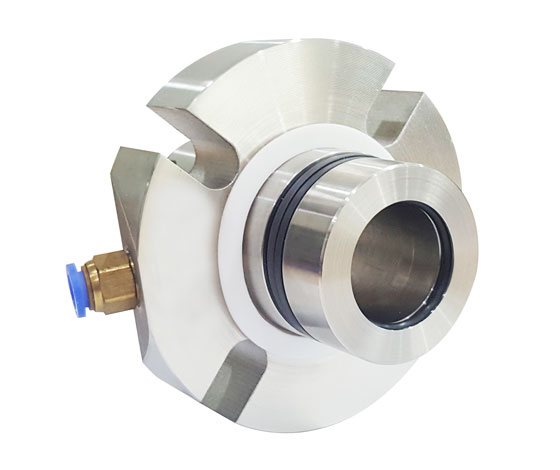

DS-320

Suitable for a wide range of services conditions.

Application

- For use in pumps, mixers, blenders, agitators, compressors and other rotary shaft equipment.

- For pulp and paper, petrochemical, food processing, wastewater treatment and other demanding applications.

Type DS-320 is a double cartridge heavy duty slurry seal designed to operate in harsh slurry. Incorporates a unique non-clogging multiple springs are isolated from liquid rich in solid impurity. Double cartridge seals prevent for avoid from dry-running in case of non-continuous liquid in processes.

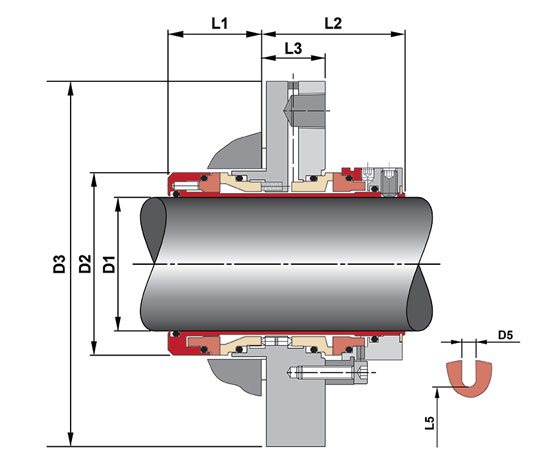

Operating Conditions

- Max. Operating Pressure : 30 kg/cm2 *

- Temperature Range : -15 to 200 *

- Max. Rubbing Speed : 35 m/s

*(Depend on combination of materials)

Design Features/Benefits

- The balanced cartridge construction makes the suitable for a wide range of demanding applications, excellent reliability, and repeatability of performance.

- Cartridge seal confguration. Easy to install and operate.

- Double cartridge seal configuration design for safety operation.

- The multiple springs are located in the stationary housing outside of the sealed liquids.

- Premium-grade silicon carbide solid seal faces are excellent for abrasion-resistant and corrosion-resistant provided seal life consistent with equipment parts.