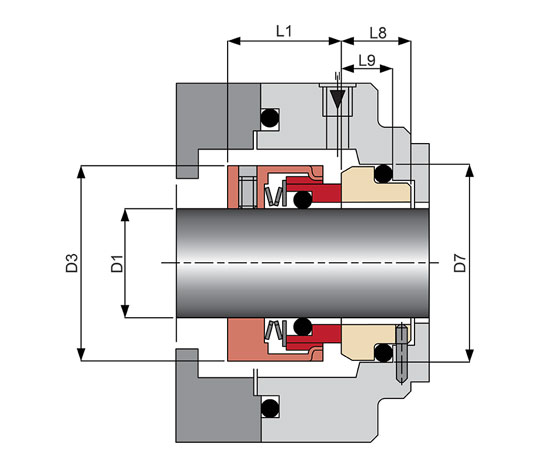

DS-7N

Subitable for a wide range of services conditions.

Application

- For use in pumps, mixers, blenders, agitators, compressors and other rotary shaft equipment.

- Suitable for most general and light chemical duties ranging from water to weak acid solutions.

Type DS-7N mechanical seal is designed for universal application. The seal face are loosely inserted and can be easily exchanged, the thrust-ring is retained by the drive lugs preventing the springs falling out.

Operating Conditions

- Max. Operating Pressure : 16 kg/cm 2 *

- Temperature Range : -15 to 200 *

- Max. Rubbing Speed : 20 m/s

*(Depend on combination of materials)

Design Features/Benefits

- The wave spring designed for install in the shallow seal chamber.

- Setting-length of spring can be held in position by build in set-ring.

- Independent of shaft rotating direction.

- Premium-grade silicon carbide solid seal faces are excellent for high temperature and enduring abrasive fluids.

Standard Materials

- Metal Parts : SUS 316

- Spring : SUS 316

- Rotary Face : Silicon Carbide/Tungsten Carbide/Carbon

- Stationary Face : Silicon Carbide/Ceramic/Tungsten Carbide/Carbon

- Secondary Seals : Fluoroelastomer/Nitrile/Ethylene Propylene

*(Other configuration of materials also available on request)