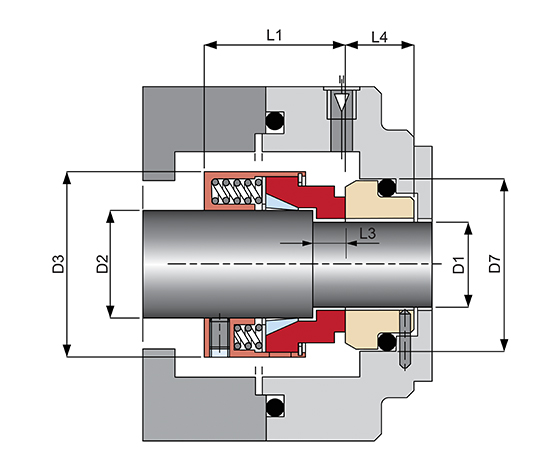

DS-400BW

Suitable for a wide range of services conditions.

Application

- General and high pressure sealing duties, chemical, including processing, refinery and petrochemical plants.

- Oils, solvents, refrigerants, water and food processing, and other demanding applications.

Operating Conditions

- Max. Operating Pressure : 40 kg/cm 2 *

- Temperature Range : -15 to 200 *

- Max. Rubbing Speed : 15 m/s

*(Depend on combination of materials)

Design Features/Benefits

- Multiple springs exert even closing force on seal faces. Ensure even loading of seal face and compensates for acceptable shaft misalignment.

- Versatile design using components common to other O-ring and wedge type seals. Allow easy repair, reduced spares holding, and simple conversation to balanced/unbalanced or wedge seal.

- Setting-length of spring can be held in position by build in set-ring.